Do you want to drill fast and safe?

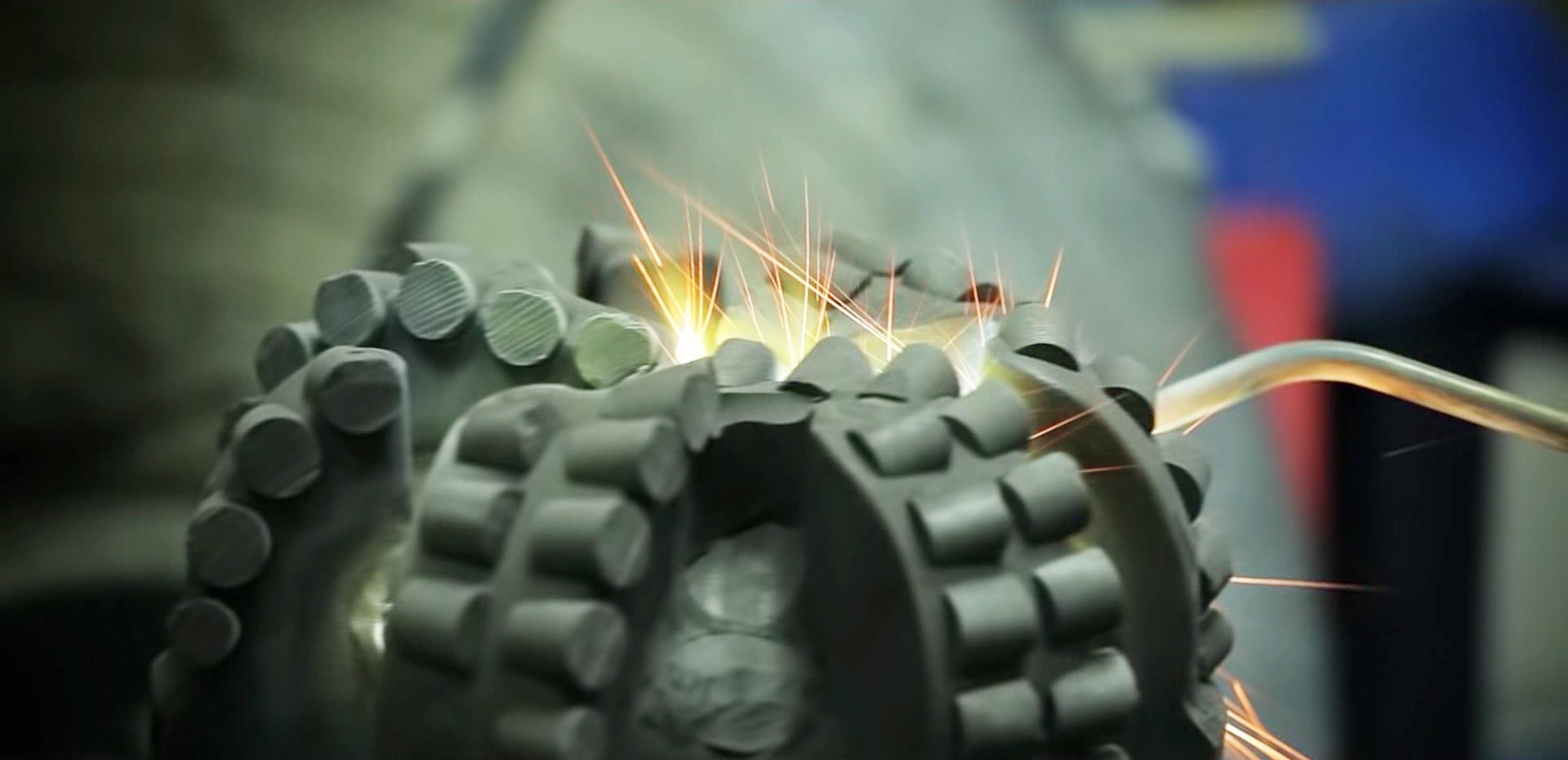

DP Service LLC offers drill bit service comprising the following:

- Assessment of geotechnical data and bit programs development

- Timely supply of rock-cutting tools to the Client according to the approved bit programs

- Engineering support for bit programs implementation on site:

- a. Preparation of drill bits to RIH, surveillance of hydraulic circulation program

- b. Drill crew training on correct utilization of drill bits and their features

- c. Engineer’s participation in the main technological operations with drill bits (BHA assembling/disassembling, passing intervals of potential complications during tripping operations, drill bit running-in at the bottom hole etc.)

- d. Assessment of the optimal drilling techniques and their operational change is necessary

- e. Assessment of the drilling stop time due to wear of rock-cutting tool

- f. Assessment of the drill bit wear

- g. Development and sending-out of daily reports on approved template

- Based on drilling results, development of final report with the detailed analysis of the applied tools, equipment, drilling techniques and suggestions on improvement of technical and economic performance for the next wells on the given field.

Drill bit service is a solution for you!

Benefits for Client:

- Reducing time and costs for well drilling due to:

- a. Optimal selection of drill bits resulting in increase of ROP and bits operational life in the bottom hole

- b. Efficient drill bits running eliminating any risks of unqualified actions of drill crew.

- Accurate drill bit expenses planning.

- Avoiding the need to maintain a large set of standby bits reducing the costs

- Availability of operational true information on drilling process and additional professional engineering support